Quick OB - Revolutionizing Operation Bulletin

Planning for Garment Manufacturers

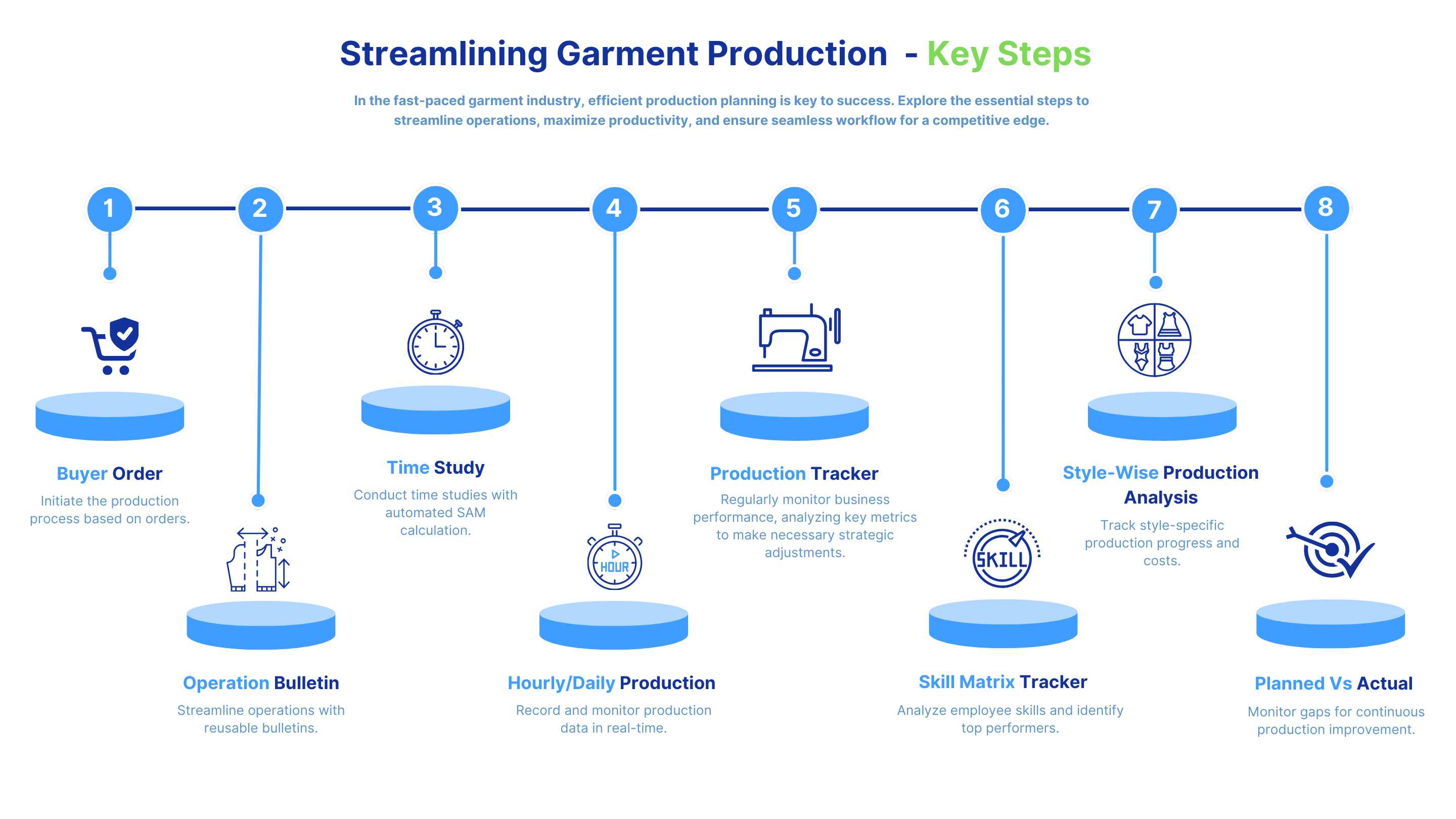

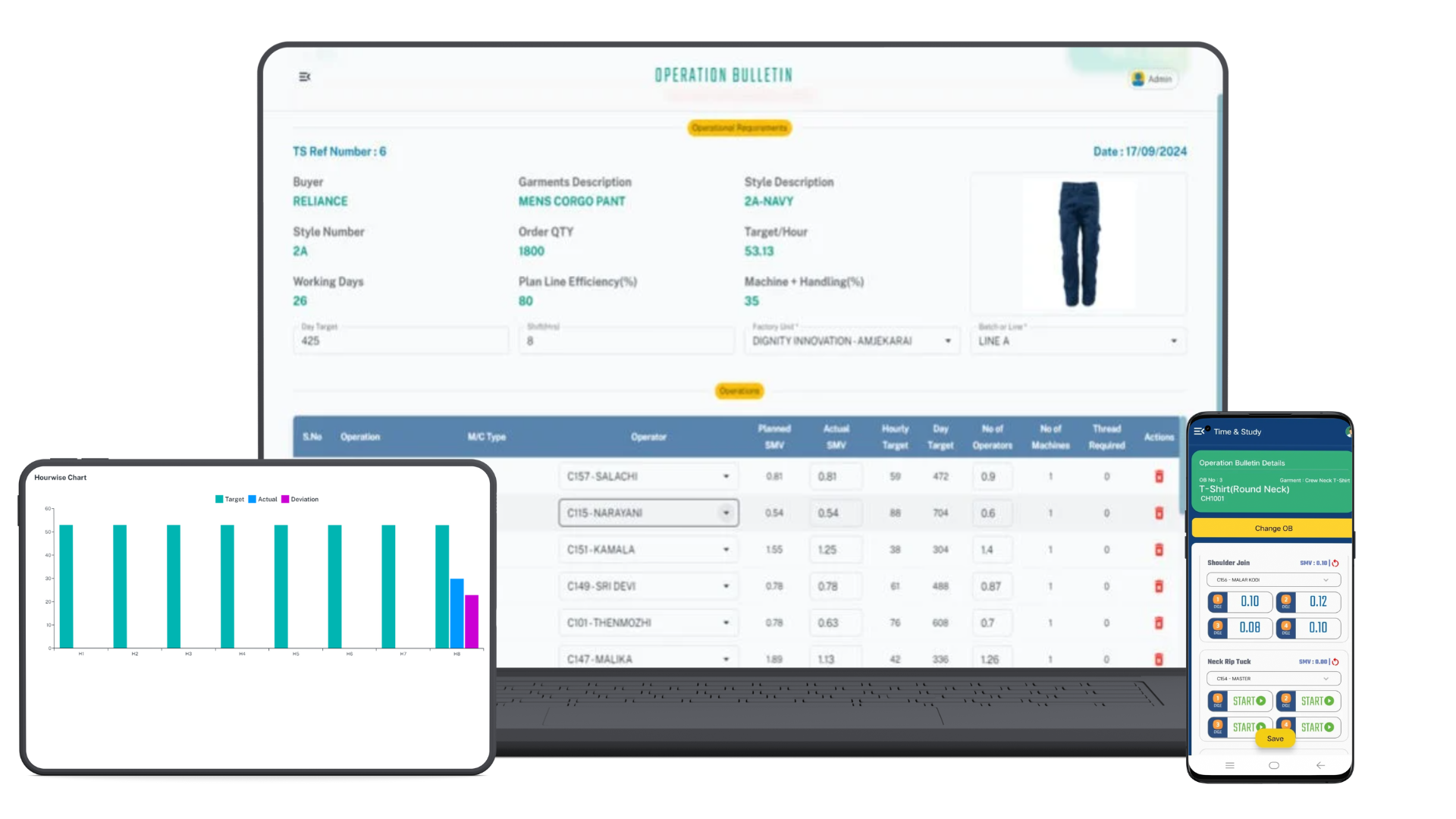

Quick OB is a user-friendly, cloud-based application designed to help garment manufacturers streamline their operation bulletin planning. It simplifies key tasks like SMV (Standard Minute Value) calculation, production planning, and performance tracking, saving industrial engineers valuable time. By digitizing manual processes, Quick OB improves accuracy, allows easy reuse of data for repeat styles, and optimizes resource allocation. With real-time monitoring and customizable reports, it supports line writers, engineers, supervisors, and management in running a more efficient and transparent production process

Functional Areas

For Industrial Engineers

For Production Line Writers

For Supervisors

For Management