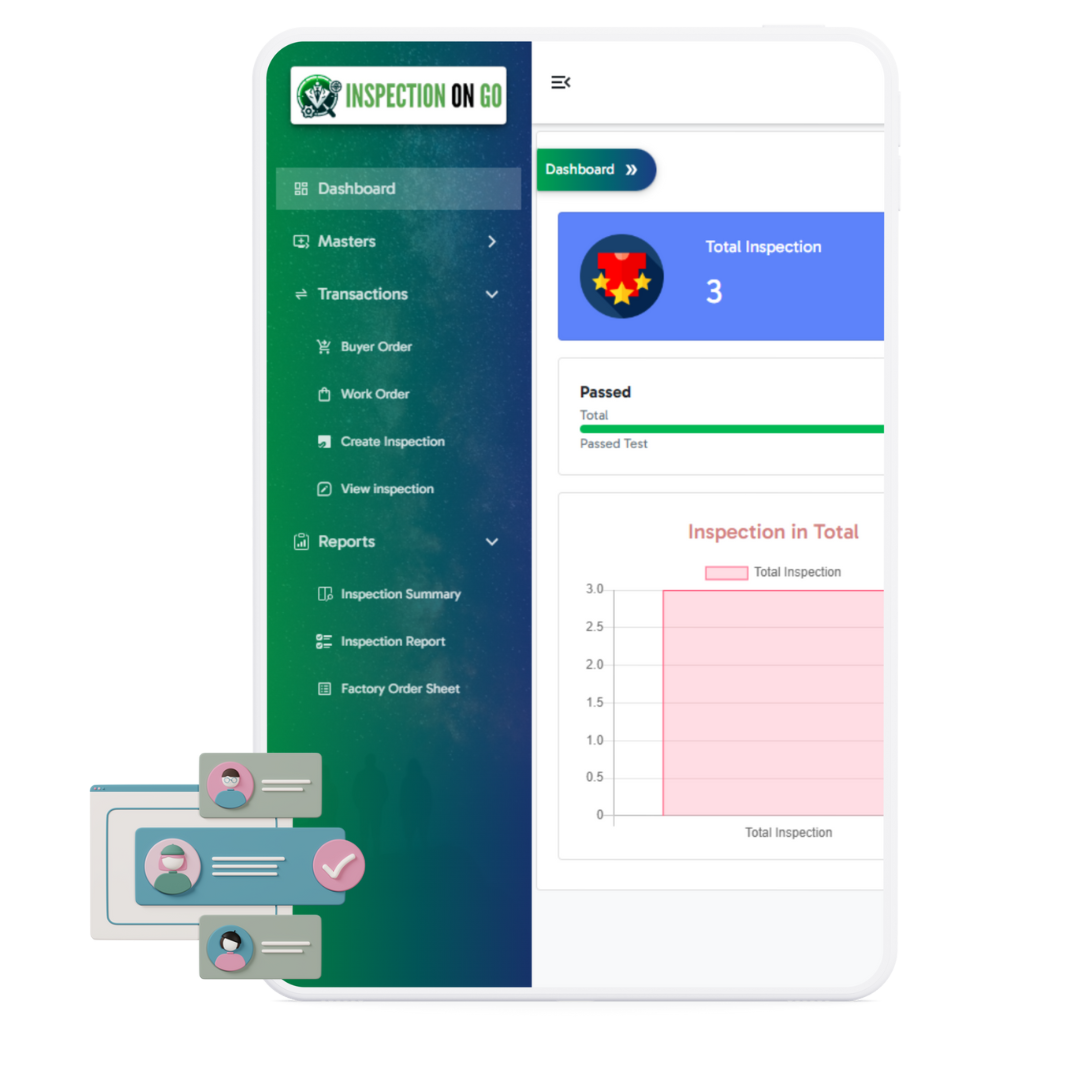

TARGET - INSPECTION ON GO

Tailored for Garment Industry Quality

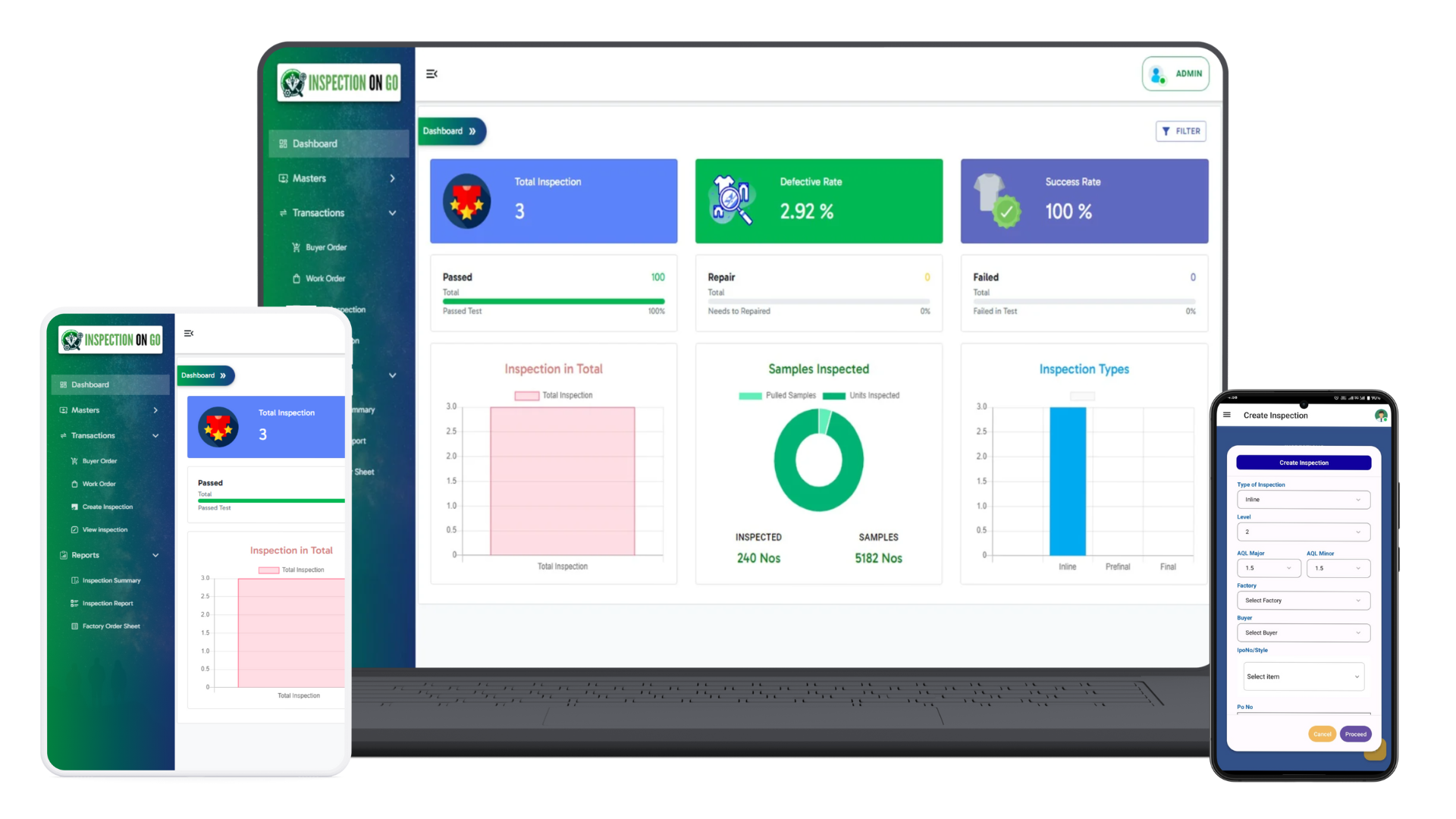

Inspection On Go is a robust solution designed to streamline garment inspection processes from order creation to quality checks, optimizing workflow and ensuring transparency at every stage. It integrates real-time monitoring, offline capabilities, and mobile accessibility to help manufacturers and quality assurance teams maintain high standards, even in remote or disconnected environments

Inspection On Go

Buyer Order Management

Seamlessly handle all aspects of buyer orders, from initial inquiry to direct order creation, enhancing efficiency and customer satisfaction.

Factory Order

TARGET - IOG structures the FOS in terms of trading. Once on generating the FOS the system provides with the Projected Profit report for the merchandiser and the management for high level expected Margin.

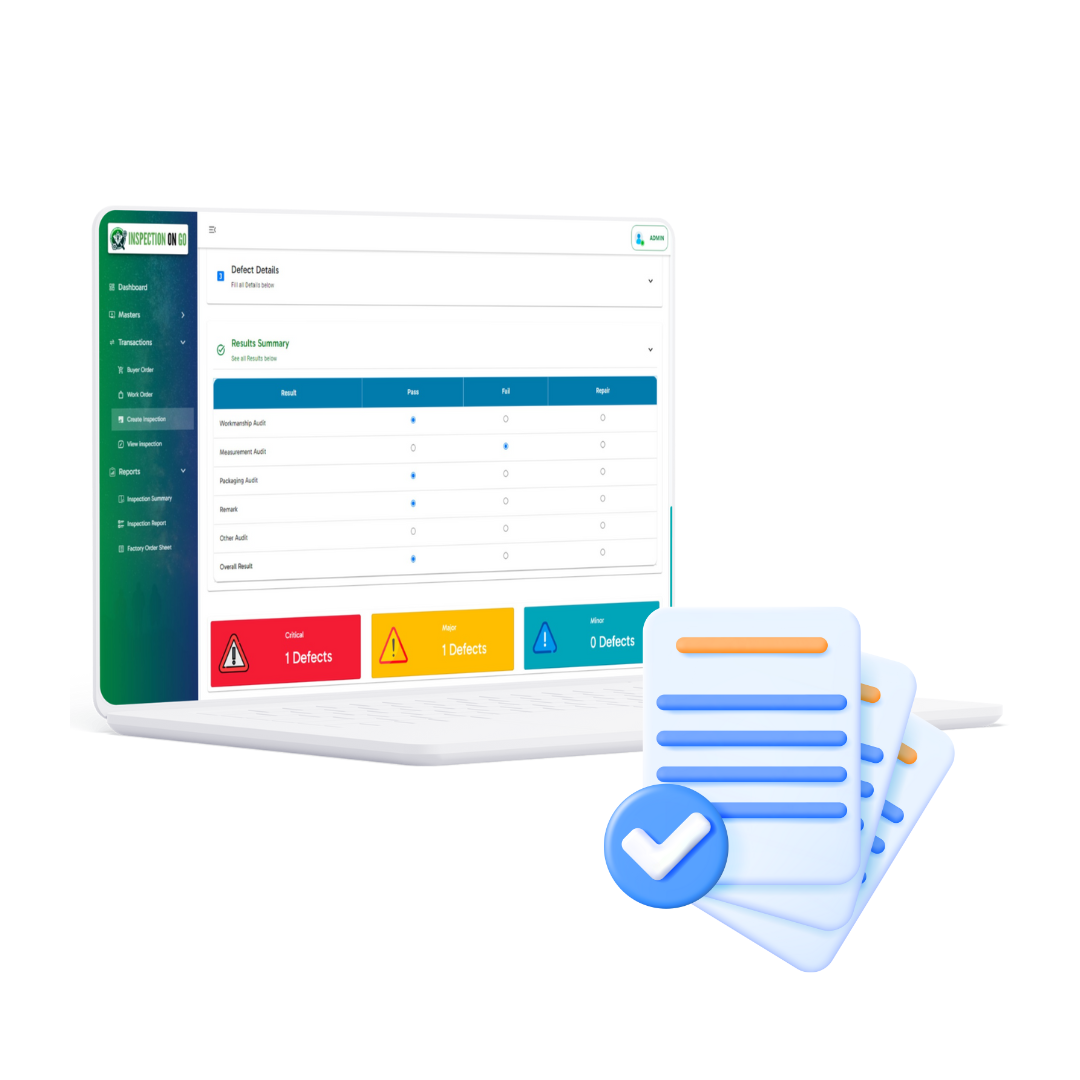

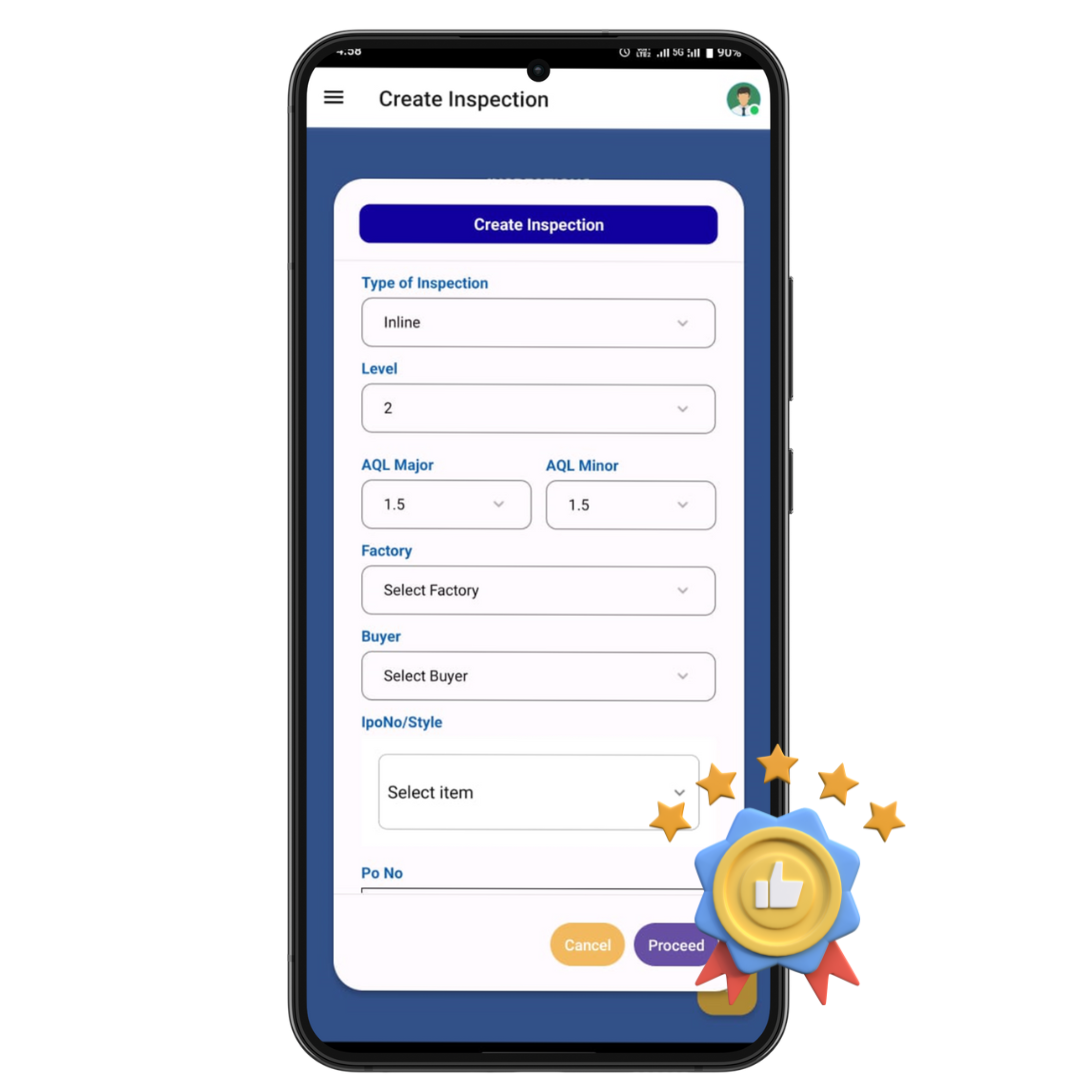

Inspection Audits

TARGET - IOG acts as a user friendly tool especially for Inspection module where the QA will be able to inspect in factory even during the crucial period without internet access. TARGET - IOG captures the data locally during offline and uploads the data back.

Access Control Management

Multi-level access control ensures only authorized personnel can access sensitive data. Access the entire organization structure from anywhere through our cloud server integrated solution.

Real-Time Reporting with Target MIS

Target MIS serves as a real-time reporting assistant, offering end-to-end traceability from Buyer Order to Factory Order and Inspection Status. It caters to various management levels by providing information in both summarized and detailed formats

Inspection On-Go for QA

Explore the unique products tailored inspections through the Target Inspection on Go module. Effortlessly configure a variety of quality check types to ensure each item is properly checked for defects. Web and Mobile Integrated Solution.

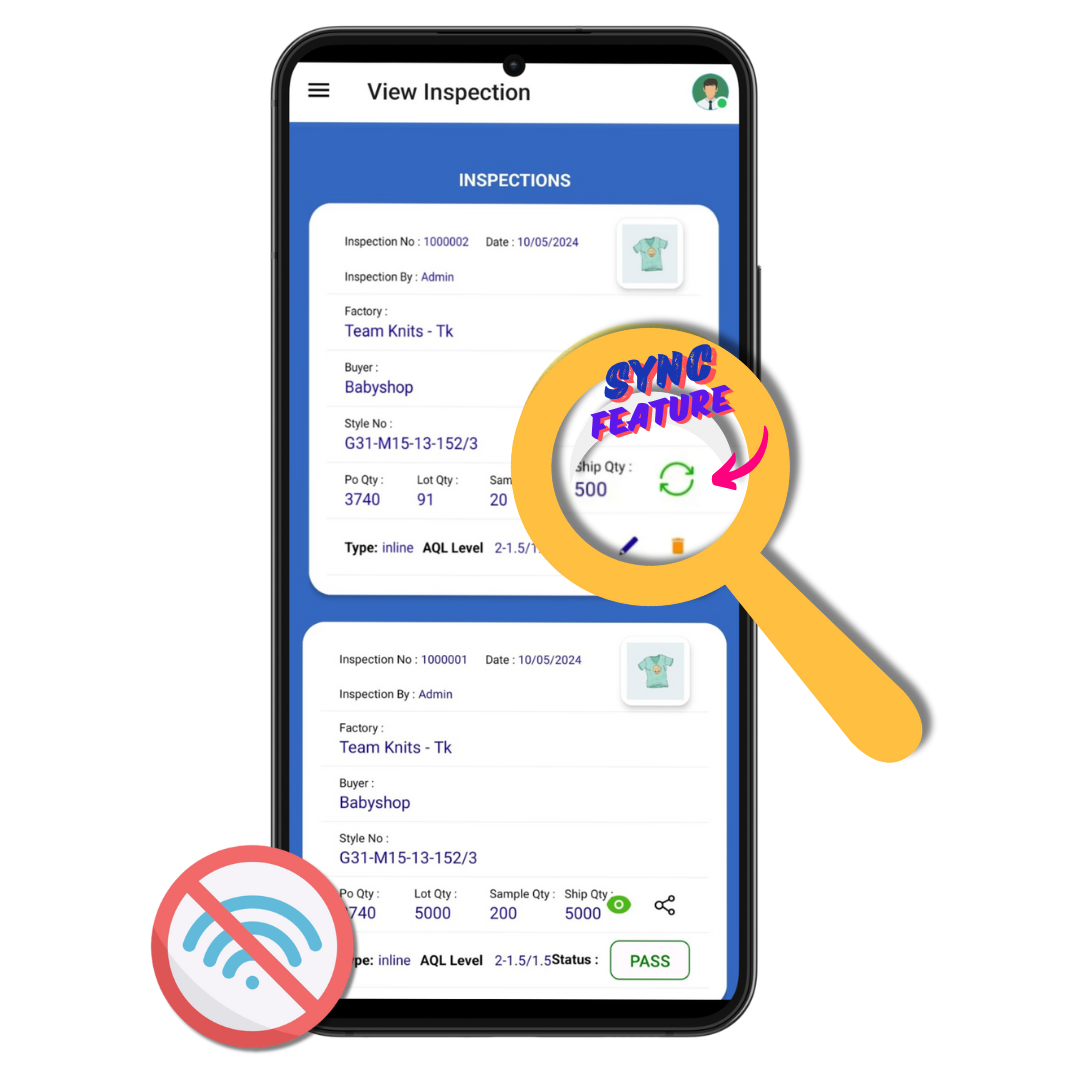

Offline Functionality & Sync Feature

Our app supports offline inspections and data recording. Once online, the sync feature updates all information seamlessly, ensuring no data loss and keeping records up-to-date on both web and mobile platforms.